Automated Deburring as Part of Modern Machining

The removal of sharp edges, burrs, and other unwanted material from machined parts is an essential step in metal workshop production. Traditionally, this process has been carried out as a separate and manual step, tying up workers in hand-finishing tasks and making the end result heavily dependent on the individual. Hand deburring using files, scrapers, or other manual tools is slow, and the final outcome can vary from one part to another. Mechanically performed manual operations, such as finishing with an angle grinder, may also yield inconsistent results and require considerable care to avoid damaging visible surfaces of the part.

Manual deburring also brings risks that can directly affect both product quality and safety. If the deburring tool slips off an edge, it can leave a permanent mark on the workpiece, resulting in a cosmetic defect or even rejection due to surface quality issues. Sharp metal chips and broken hand tools can cause cuts or eye injuries, leading to work interruptions and increased risk of workplace accidents. For these reasons, moving deburring into a controlled and automated process has become a key development focus in many machine shops.

When deburring is done with a CNC machine, all parts are finished in the same, controlled, and repeatable way. This improves the overall product quality and reduces the chances for errors, while machine operators’ time is freed for other productive tasks, like preparing the next job, maintaining tools, or developing process efficiency.

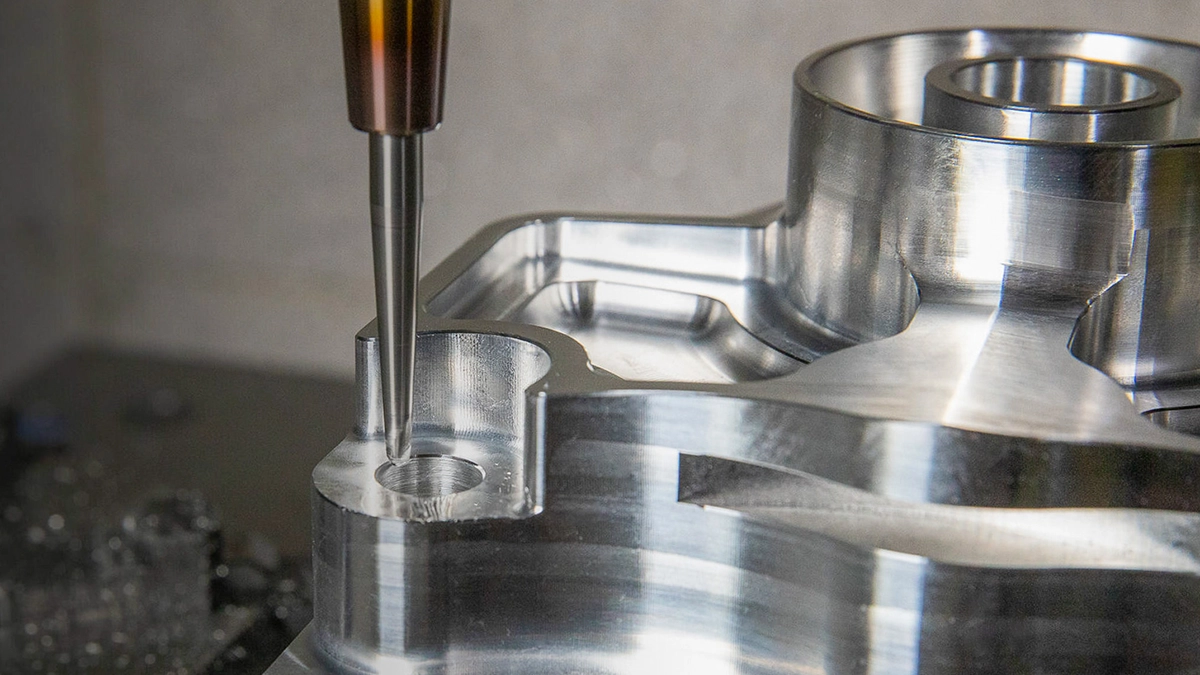

Mastercam Deburr introduces an automated, solid-model-based programming method for deburring, where edge finishing is completed directly on a CNC machine as part of the normal machining process. The core of Mastercam Deburr is automatic edge detection and safe toolpath calculation. After the user selects the part, the program analyzes its geometry and creates an optimized toolpath for burr removal, simultaneously taking care of collision avoidance and accounting for both part geometry and specified avoid surfaces.

Consistent Results on Inclined Surfaces and 3D Shapes

The difference between Mastercam Deburr and traditional Profile toolpaths is especially clear when the edge to be finished sits on an inclined or contoured surface. Profile toolpaths create chamfers based on planar chains, so the size of the chamfer varies depending on the surface’s tilt angle. Large changes in tilt can lead to uneven finishing or excessive material removal.

A toolpath generated with Deburr keeps the set deburring width consistent along the entire edge to be finished. Deburr evaluates the part in three dimensions and adjusts the tool's path according to the surface shape, so the edge finishing stays uniform even on curved or variable surfaces. The toolpath is uninterrupted and requires no manual trimming, saving programming time and increasing process reliability, especially on 3D-shaped parts.

Deburring in Different Machining Environments

Mastercam Deburr is a standalone feature that can be added to Mastercam Mill and Mill 3D environments whenever 3-axis automated deburring is desired as part of machining. In these cases, automated edge finishing is ideal for traditional machine shop parts, where most burrs appear on the upper and side surfaces. Automatic edge detection and managed toolpaths enable consistent finishing even on inclined and shaped surfaces, eliminating the need for manual touch-up.

If you’re using the Mastercam Multiaxis environment, Deburr functionality is included as part of the package. Here, deburring covers all the familiar features of 3-axis operations but expands to 4-axis, automated 3+2 axis, and full 5-axis tool axis control. This allows edge finishing from multiple machining directions, which is necessary when part geometry, undercuts, or hard-to-reach areas like intersecting holes require tilting the tool.

Automated deburring isn’t limited to just machine tools. If production uses part-handling robots or cobots, toolpaths created with Mastercam Deburr can be transferred to robotic applications using Robotmaster software. The toolpaths are converted to programming languages robots understand, and all robot arm motion, reach, and potential collisions can be virtually simulated before going into production. This supports automated deburring in robotic cells, enabling flexible and safe production, especially in batch manufacturing.

Tool Solutions for Deburring

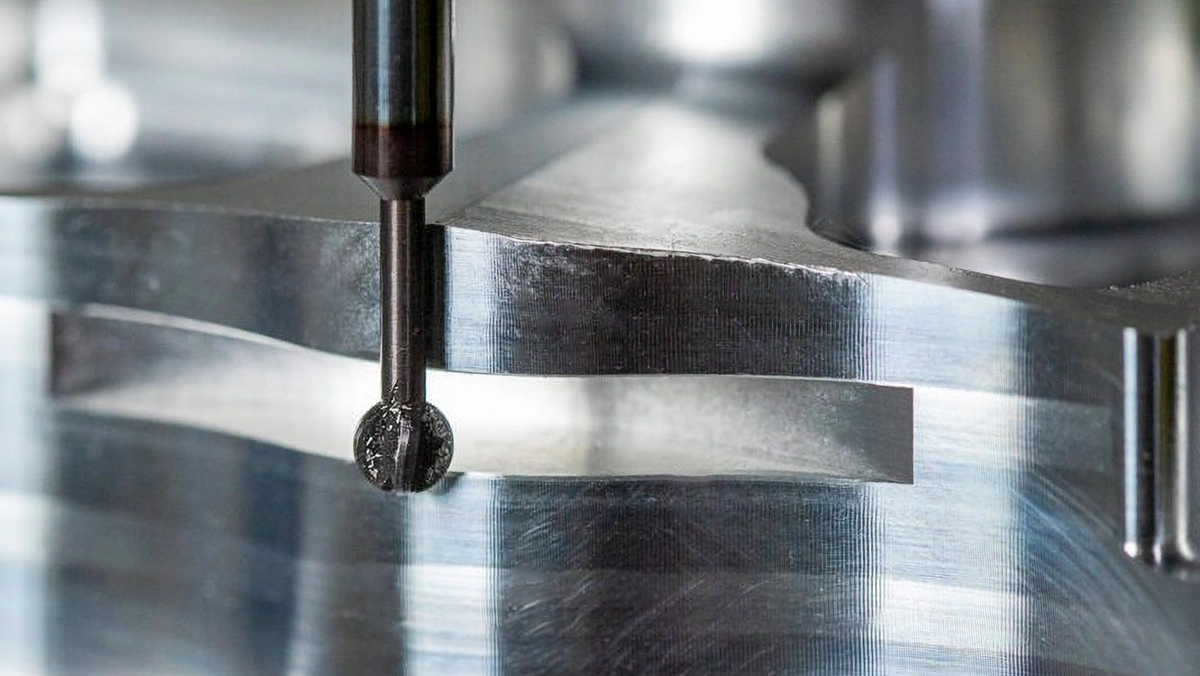

Deburr supports a wide variety of cutting tools for removing burrs and sharp edges. In addition to standard chamfer mills, you can use ball-end mills to achieve a smooth and controlled deburring result even on complex and inclined surfaces. "Lollipop" shaped end mills, on the other hand, make it possible to finish undercuts, intersecting holes, and other hard-to-reach geometries that would otherwise have to be finished by hand.

Automated deburring is especially advantageous for undercuts and partially enclosed geometries. Deburr guides the tool safely through narrow gaps and complex surfaces, ensuring that the tool shank and holder don’t contact the part. Burr removal remains consistent along the entire toolpath without manual adjustment or compromise in the result.

Users can precisely specify the avoidance distances for the toolholder, shank, and neck relative to the workpiece or any geometries to be avoided, such as fixtures, improving safety and process control during machining.

Support for Deburring Automation

As the official reseller and trainer for Mastercam software, Camcut supports machine shops in implementing and effectively utilizing Mastercam Deburr. Their services include software licensing, deployment, and training that helps integrate deburring into a smooth and safe machining process. A practical approach ensures the software’s features support production requirements specific to each shop’s machining and product needs.

Camcut also provides technical support and consulting on programming Deburr toolpaths, selecting tools, and developing machining processes. If needed, Camcut can also offer programming services for deburring or complete machining projects, taking into account the customer's production characteristics, machine base, and batch sizes. The goal is an effective and repeatable machining solution that enhances both productivity and quality.

In addition to software services, Camcut also offers tools suitable for deburring, such as "lollipop" end mills for undercuts and other challenging geometries. The integration of software, tools, and methods can thus be managed reliably as part of the production process.

Camcut’s website offers extensive support materials for self-learning and daily use of Mastercam. Users have access to instructions, practical examples, and toolpath descriptions, helping them deepen their skills and make the most of Mastercam’s possibilities as their production evolves.