Walter Tools product innovations 2025-2: new solutions for efficient and reliable machining

The German cutting tool manufacturer Walter Tools is once again unveiling an extensive range of new products and product family expansions, further solidifying the company's position as a leader in the development of cutting tools. The Fall 2025–2 launches include around 1,600 new products, 22 completely new product families, and several significant extensions to existing series. New products have been introduced across all main areas—drilling, threading, turning, and milling—as well as in coating technology and digital tool solutions. These new tools have been developed to boost machining productivity, tool life, and process reliability, even in the most demanding serial production conditions.

Camcut, the official Walter Tools distributor in Finland, will soon have these new products available in its online shop, which features real-time stock balances, customer-specific prices, and downloadable 3D models. Below, Camcut highlights a selection of Walter Tools’ latest innovations—solutions that represent the latest developments in the world of cutting tools.

Drion·tec® E-Peak D5150 – Next Generation High-Performance Indexable Drill

The new Drion·tec® E-Peak D5150 sets a new benchmark for efficient and reliable drilling. It is designed to deliver top productivity and versatility across all material groups—with just one drill tip geometry. The indexable drill series covers diameters Ø9.00–17.99 mm and is available in lengths of 3xD, 5xD, and 8xD. The D5150 is specially developed for production environments that require long tool life, high feed rates, and excellent hole quality. The optimized drill tip geometry ensures controlled chip formation even in long-chipping materials, and the interchangeable tips’ WPP35G (AlTiN) and WMS35G (AlTiCrN) PVD multi-layer coatings combine wear resistance and toughness for challenging materials. The variable helix flute design increases rigidity and chip evacuation, which is especially important in deep hole drilling.

The E-Peak D5150 is perfectly suited for uneven and intersecting surfaces as well as so-called stack drilling. It can also drill inclined surfaces—entry angles up to 10° and exit angles up to 30°—without tool wander or vibration. Thanks to its approximately 158° point angle, the drill centers itself reliably and produces holes in the H9/H10 tolerance class, maintaining excellent cylindrical shape throughout the drilling depth. The drill body is engineered for robust and long-lasting use, and its patented pre-stressed clamping mechanism enables multiple tip changes without fatiguing the holder. Tapered contact surfaces ensure precise centering of the drill tip and evenly distribute cutting forces, while axial locking grooves prevent the tip from coming loose during the process.

Drion·tec® D-Spade D5142 – Cost-Effective Double-Sided Indexable Drill

The Drion·tec® D-Spade D5142 is the world’s first indexable drill featuring a double-sided insert, providing two cutting edges on one tip. This solution doubles tool life and reduces overall costs. The four-guide-edge tip ensures precise drilling even on inclined surfaces and when crossing holes. The D5142 is suitable for ISO P and ISO K material groups, and its range is expanding to cover 8xD lengths and diameters up to 31.75 mm.

New F57 Geometry – Easy-Cutting Solution for Indexable Drilling

Completing the drilling lineup is the all-new F57 geometry, developed especially for long-chipping materials like non-alloyed and stainless steels. The new geometry improves chip management and reduces cutting forces, enabling higher feeds and longer tool life. F57 is particularly suitable for challenging applications such as intersecting holes, inclined exits, uneven starting surfaces, and rough drilling.

F57 is available for Drion·tec® D3120 and D4120 indexable drills, providing up to 30% higher feed rates and tool life compared to previous geometries. For the first time in indexable drilling, the Wiper geometry is directly produced during the compression (Direct Pressed) process. The Wiper geometry delivers exceptionally good surface finish and hole dimensional accuracy.

Drivox·tec™ Ikon DD170 – Expanded Selection and Longer Drilling Depths

The Drivox·tec™ Ikon DD170 solid carbide drill family is expanding with new drilling depths and diameter ranges. The selection now covers drilling depths from 3xD to 40xD, making the series an even more versatile solution for deep and precise hole drilling in various materials. The DD170 is based on the same technical platform as the award-winning DC170 Supreme, but offers several advanced improvements, such as the Krato·tec® multi-layer coating, which extends tool life by up to 50%. The number of guide edges has been increased, allowing the drill to be resharpened several more times than before. The redesigned tip geometry and optimized flutes improve tool centering, reduce axial forces, and improve process reliability—especially in inclined and intersecting drilling.

TD610 Supreme – New Solid Carbide Thread Milling Cutter

The new TD610 Supreme represents Walter’s latest advancement in solid carbide thread mills. The newly designed shank geometry reduces stress and increases stability, helping to prevent tool breakage—especially at high feed rates. Unequal pitch cutting edges ensure light and vibration-free machining, while the new coating technology combined with a tougher carbide grade extends tool life. Improved wear resistance minimizes the need for tool radius compensation on the machine and makes this tool the ideal choice for demanding serial production.

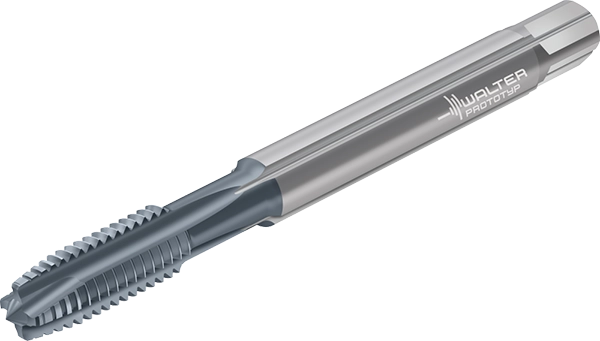

TC180 Supreme and TC280 Supreme – New Product Families for Threading

Walter is expanding its Supreme product family with two new solid carbide tap series. The TC180 Supreme utilizes advanced HIPIMS coating for an extremely dense and wear-resistant surface. The tool’s negative cutting edge geometry breaks chips short and prevents fractures, making it an excellent solution for tapping softer steels and ISO P, K, and N materials.

The TC280 Supreme uses the same coating technology, but is specially designed for high-volume production. The tap shank’s straight cooling grooves improve coolant flow directly to the cutting zone, enhancing heat management and process reliability. Thanks to these features, the TC280 Supreme delivers excellent tool life and stable performance in demanding production environments.

Expansions to the WL Copy Turning System

Walter’s WL copy turning system has received significant extensions to its range of inserts. The WL copy turning tools offer up to 50% higher indexing accuracy compared to conventional VBMT inserts. The three-edged WL17 and WL25 inserts deliver excellent surface finish and allow bi-directional machining without changing the insert. The range has been expanded with four new geometries—FM2, MN2, RM4, and RP4—covering both finishing and roughing applications. FM2 is particularly suited for precise finishing of stainless steels, while MN2 is a highly efficient solution for turning aluminum and other non-ferrous metals. RM4 and RP4 are designed for heavy roughing in various material groups, delivering outstanding chip control and repeatable surface quality. The new round-nose WL inserts, designed for dynamic turning, are available with nose radii from R1.0 to 3.0 mm, offering the same secure and precise clamping cost-effectively with three cutting edges for dynamic turning applications. The expansion makes the WL system an even stronger choice for a variety of copy turning applications.

Groov·tec™ GD – Expanded Parting and Grooving Program

Walter Tools' Groov·tec™ GD26 parting and grooving system is expanding to cover even broader applications and use cases. The new generation GD26 inserts utilize a patented double-sided multi-groove clamping system, which increases the insert contact area with the toolholder. This significantly improves insert stability and side support, resulting in less vibration and longer tool life. The insert’s elevated top face profile enhances chip control, resulting in improved surface quality and controlled chip formation—even in the most challenging conditions. The GD26 system is suitable for both radial and axial turning as well as parting-off operations.

The expanded GD range now includes multiple new holders and geometries. The new G5011-C-P Capto holders offer through-coolant above and below for 3–6 mm insert widths, and the G5011-P and shank holders now come in shank sizes from 12×12 mm to 32×32 mm. Additionally, new G5111 axial turning holders are suitable for face grooving in diameter ranges of 35–500 mm, and with the G5511 universal holder, the same tool can be used for both axial and radial turning with 2.5–6 mm insert widths up to 8 mm depth. The GD product family is further enhanced by new G5042 universal parting blades, including the G5042-P version with through-coolant on both sides, as well as G5041 screw-clamped parting tools that combine robust construction and greater stability compared to traditional parting blades. The effectiveness of the GD26 system is rounded out by the new VG7 and CK8 chip breaker geometries. The uncoated CK8 is suitable for ISO N and ISO S materials, delivering outstanding surface finish and chip control, while VG7 utilizes WSM23G and WSM33G insert grades and is particularly effective for back turning and fine finishing operations.

Tiger·tec® Gold WPP35G – New Carbide Grade for Milling

The new WPP35G carbide grade extends Tiger·tec® Gold coating technology to milling and replaces the current WKP35S grade. The multi-layer coating combines MT-TiCN and Al₂O₃ layers, offering excellent wear resistance, thermal crack control, and long tool life even at high temperatures. The top layer of golden TiN coating makes it easy to identify wear visually and ensures optimal replacement intervals. WPP35G is especially suited for machining steel and cast iron and is compatible with all major Walter milling product families, such as Walter BLAXX, Xtra·tec® XT, and M4000.

Walter GPS – Smarter Than Ever Tool Selection System

Walter GPS receives major upgrades that make selecting and using tools in production even easier. The system now broadly supports milling operations: corner, pocket, copy, and slot milling are available with no previous limitations, adding flexibility and giving users more freedom in machining strategy planning. The threading module has been updated to include multi-row thread mills with axial chamfers, as well as support for an extra finishing pass with universal thread mills like the TD610. The user interface has been redesigned for greater user-friendliness: the new “Add to favorites” feature now also saves search results and settings, making it easier to compare tools and keep records. Additionally, sharing customized machine profiles within an organization has been streamlined—users can share machine profiles internally without separate file downloads, simplifying collaboration and maintenance.