SAV and TDG Clamping Solutions have combined their expertise

Two European leaders in clamping technology, the German company SAV GmbH and the Spanish company TDG Clamping Solutions, have joined forces to develop a new type of self-centering magnetic chuck. This solution combines electro-permanent magnetic clamping with mechanical jaw technology to improve machining accuracy, reduce setup times, and enhance production safety.

The collaboration leverages the strengths of both manufacturers: SAV is renowned for its development of electro-permanent magnetic clamps and automatic workholding solutions, while TDG brings over a century of experience in manufacturing large and custom chucks. By combining this expertise, they have created a new generation of clamping solutions that meet the rising demands of modern machine workshops.

SAV GmbH – A Pioneer in Magnetic Clamping

SAV GmbH traces its roots back to 1984 in Nuremberg, and over four decades, the company has become one of the world’s leading developers and manufacturers of magnetic clamps. The company is guided by the principle Power. People. Passion.—strength, expertise, and passion upon which SAV has built its reputation as a technology leader.

SAV’s magnetic clamps are used worldwide in milling, turning, and grinding applications. The company is known for numerous innovations, such as the world's first magnets designed for hard turning and hybrid systems that combine the properties of AlNiCo and neodymium magnets to achieve extremely high holding forces.

SAV has invested in the development of electro-permanent magnetic clamps for decades. These systems operate by activating a magnetic field with a short electrical pulse, after which the field remains active without continuous power. This makes the system safe, energy-efficient, and heat-free. Power is needed only during magnetization and demagnetization, so power outages do not affect the holding force.

SAV’s solutions emphasize practical efficiency and repeatability. Magnetic clamping distributes the holding force evenly across the entire contact surface, minimizing workpiece deformation and enabling extremely precise machining. Thanks to these features, SAV has secured its position as a pioneer in magnetic clamping technology and a trusted partner across various industries.

SAV’s technology is widely utilized in industries such as automotive and machine tools, precision part manufacturing, renewable energy production, oil and gas, rail and gear system manufacturing, agricultural machinery, medical technology applications, and aerospace.

TDG Clamping Solutions – Over a Century of Expertise in Heavy Industry Chucks

Located in the Basque Country, the industrial heart of Spain, TDG Clamping Solutions was founded in 1916 as Talleres de Guernica—“the Guernica Workshop.” Over more than a hundred years, the company has grown from a local workshop to a global player with products in over 60 countries on every continent. Today, TDG is part of the Cosimet Group and collaborates with partners like Geminis, Gurutzpe, Soraluce, and Ibarmia to develop customized holding solutions for demanding heavy industry machining tasks.

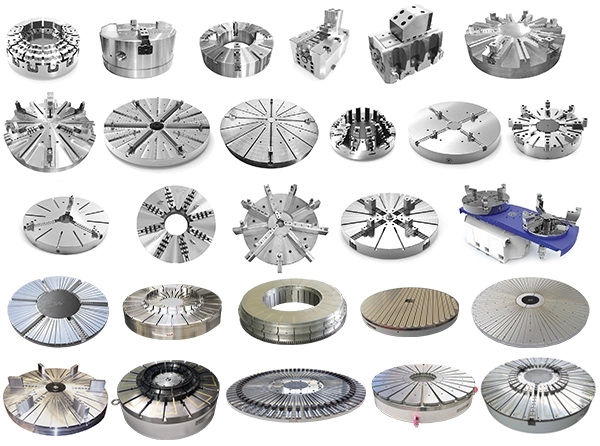

TDG specializes in manual and hydraulic chucks, with a particular focus on large-diameter and custom solutions. The company manufactures chucks up to seven meters in diameter, enabling safe, stable, and precise clamping of very large and heavy workpieces. The product portfolio also includes support jaws and jaw boxes for large parts, exchange and zero-point systems, and the innovative TDG Smartchuck, which brings real-time monitoring and process data to the clamping process.

TDG’s strengths lie in its in-house design and R&D team, modern manufacturing methods, and flexible customer-oriented approach. The company’s chucks are used especially in industries handling large and demanding components, such as aerospace, rail, marine, wind energy, and oil and gas. In these sectors, precision, safety, and durability of the clamping system are critical, and TDG has secured its place as a reliable partner for these applications.

The New Self-Centering Magnetic Chuck Combines Magnetic and Mechanical Clamping

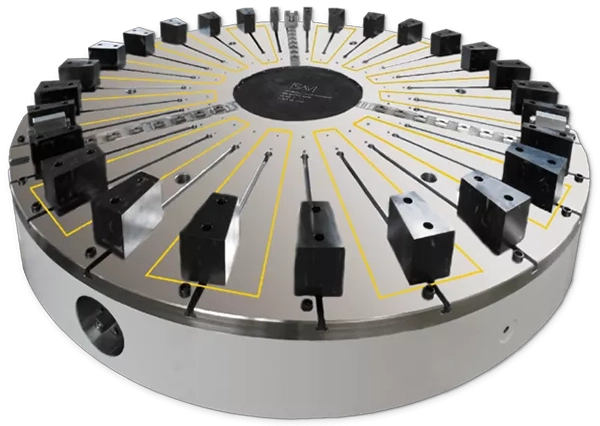

The collaboration between SAV and TDG has resulted in a new self-centering magnetic chuck that integrates electro-permanent magnetic holding with hydraulic jaw mechanics into a unified solution. Model number 244.76 is the first chuck jointly developed by SAV and TDG, designed for large and demanding workpieces typical of both companies' clientele.

The electro-permanent magnetic system utilizes neodymium magnets, providing a holding force of up to 170 N/cm². The magnetic field is activated with a brief electrical pulse, after which the chuck remains magnetically active without consuming power. Demagnetization occurs with a reverse pulse, ensuring safety and reliability—even in the event of a power failure, the magnetic holding force is not lost.

The self-centering design is based on radial pole distribution and TDG’s expertise in large hydraulic jaw systems. The integrated jaw system automatically and repeatedly centers the workpiece. Clamping accuracy is up to 0.05 mm, and the system is suitable for workpieces from 450 mm to 7000 mm in diameter. Its compact design, with a height starting at 170 millimeters, allows model 244.76 to be used in large turning cells and horizontal machining centers.

By combining the even holding force of SAV’s magnetic technology with the axial rigidity of TDG’s mechanical jaw design, the solution delivers stable clamping with minimal deformation. This reduces setup times and improves surface quality, especially when machining demanding parts like wind turbine hubs, large bearings, heavy housings, and other energy and process industry components.

The chuck can be integrated directly into the machine tool’s control system. The control unit offers eight adjustable holding force levels and an automatic demagnetization cycle, making it especially convenient for use in automated production cells. The entire construction is protected to IP65 standards, ensuring durability even in demanding machining environments.

Camcut Brings SAV and TDG Solutions to Machine Shops

The new self-centering 244.76 magnetic chuck and other SAV and TDG clamping solutions are available through Camcut. As the official importer for both manufacturers, Camcut works closely with them to ensure customers have up-to-date information and full factory support to find the right solution.

Camcut’s experts will help you choose the right clamping solution for heavy industry needs—whether it’s turning, milling, grinding large workpieces, or other demanding machining applications. Close cooperation with the manufacturers ensures direct access to factory expertise and technical resources in solution finding.