Walter GPS – the digital tool navigator that delivers comprehensive support to machine shops

Walter GPS is a free digital application developed by Walter Tools, available for both computers and mobile devices in multiple languages. Its core idea is to provide users with a simple yet technically comprehensive tool to find the right tool recommendations and optimal cutting parameters based on the given inputs. It goes beyond just the cutting tool and the workpiece material, incorporating the machine's specifications and the workpiece clamping into its calculations. Users can select from ready-made general machines or precisely define the details of their own machine. You can enter the machine’s maximum spindle speed, cutting power, and cutting torque, as well as torque and power diagrams for different speed ranges into the database. Using this data, Walter GPS gives recommendations that meet both the tool and material requirements and the machine’s actual operating limits. This makes its recommendations realistic and practical for everyday work.

The application also considers economic aspects. Walter GPS calculates the tool’s productivity—that is, the metal removal rate—and estimates the calculated tool life. Based on these, it provides a tool recommendation that is not only technically feasible but also the most cost-effective solution. The calculations take into account the tool price and the machine's defined hourly cost, giving the user a complete overview of expenses and allowing for the comparison of different alternatives. In addition, the application shows machining time and total costs for the selected values. In this way, GPS acts as a kind of digital production planner, providing users with fact-based decision-making support.

Walter GPS includes an extensive material library, allowing users to search for workpiece materials according to several different material standard designations. It displays the default material strength, which can also be adjusted as needed. Walter GPS provides equivalencies between different standard markings, making it an excellent tool for verifying rare or unfamiliar material codes. The most common materials can be marked as favorites, so they appear first in the menu. The user-friendly interface ensures that the necessary information is easy to find both on a workstation and mobile device. And because the app is entirely free, it is truly accessible to everyone.

The method selection covers the full range of machining operations

The strength of Walter GPS is its extensive support for machining methods. The application covers virtually all common cutting techniques and their various variations. For milling, it supports face milling, shoulder and side milling, plunge milling, pocket milling of different shapes, slot milling in straight and curved forms, as well as 3D surface machining with both ball nose and segment cutters. For turning, GPS provides recommendations for external roughing and finishing in both axial and radial directions, parting-off and grooving, dynamic turning, threading, and center drilling. In hole making, the app offers drilling solutions for both blind and through holes, including angled entries and exits, intersecting holes, and step drilling. It also offers solutions for chamfer drilling, step drilling, and rough and finish boring. For threading, GPS supports both cutting and forming taps as well as thread mills, and it can also suggest the correct pre-hole size and suitable tools for making the thread pre-hole.

The wide selection of methods makes Walter GPS a valuable tool for both job shops producing single parts and large batch manufacturers. The strength of the application lies in having all the information in one place, reducing the need for scattered tables, calculation formulas, and external manuals.

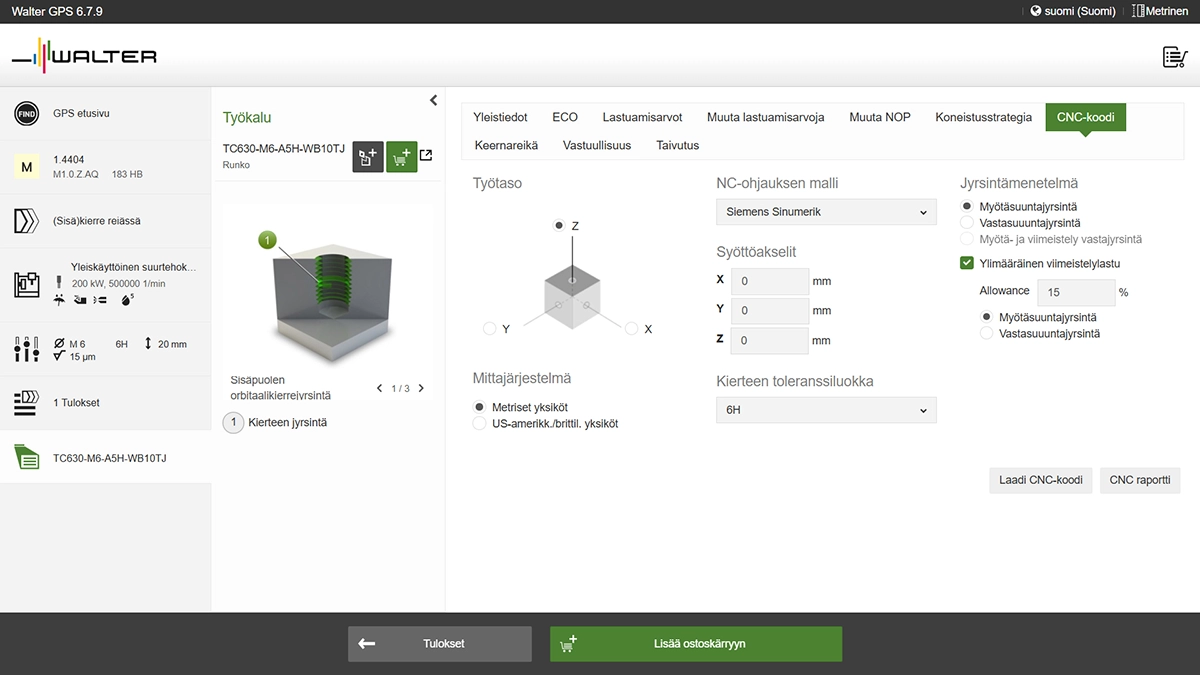

NC code generation for thread milling

Walter GPS isn’t limited to recommendations and calculations—it can also generate ready-to-use program code for thread milling. Walter GPS can create NC code for thread milling operations for specified coordinates according to the selected machine control, including the correct cutting parameters. This reduces manual programming work, saves time, and lowers the risk of errors. The application supports commonly used industrial controls such as Fanuc, Heidenhain, Mazatrol, Siemens Sinumerik, and others. NC code generation is a concrete example of how Walter GPS bridges digital design and practical production.

Partnership between Walter Tools and Camcut

Walter GPS is backed by over a hundred years of expertise. German company Walter Tools was founded in 1919 and has grown into one of the world’s leading manufacturers of cutting tools. The company is known for its high-quality products and continuous innovation. Camcut has established itself as a supplier of tools, software, and expert services for machine shops. It is the only Channel Partner Gold level reseller of Walter Tools operating in Finland.

Camcut is also well-known for its free mobile app, which brings together a wide range of machining calculators, standard and tolerance tables, and practical guides. The app can, for example, calculate coordinates for bolt circle patterns, cutting values, and thermal expansions, as well as reference ISO and geometric tolerances. It’s a valuable aid even for shops without access to CAD/CAM software or CNC machines. The app also contains links to Walter GPS, so users can access the full digital toolkit in one place.

You can most easily find Walter GPS by clicking the green Find button in the lower-left corner of the Camcut website. Once the suitable tool is selected, the recommendations can be added directly to the Camcut online store’s shopping cart, where you can see product availability. At the same time, you can download a detailed 3D model for closer inspection or a lighter simulation model for importing into CAM software or a machine simulation environment. In this way, design, purchasing, and production come together seamlessly, saving time and improving everyday efficiency in the machine shop.