Walter Tools WL – Copy Turn System | The new standard in turning

The Walter Tools WL copy turning system has established itself as the new standard in turning, as it replaces multiple traditional turning tools with one stable, precise, and cost-effective solution. At its core is the WL insert clamping system, where the insert and insert seat meet via a prismatic structure with three contact surfaces very close to the cutting zone. This ensures the insert cannot move and the insert seat does not deform due to micro-movements of the insert. As a result, the indexing accuracy of the insert improves by over 50% compared to conventional ISO insert geometries, resulting in a highly accurate turning process, excellent surface quality, and reduced need for tool offset adjustments even in series production.

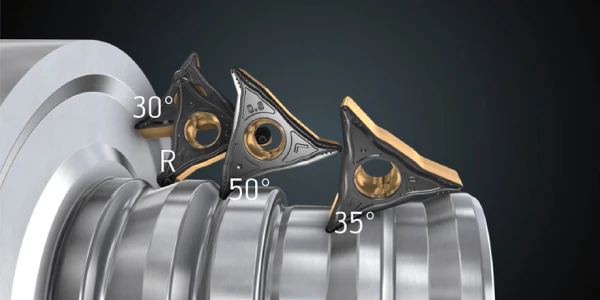

Thanks to its unique insert support, the WL system is exceptionally stable, especially in copy turning, even at profile infeed angles of up to around 50 degrees. Vibration is reduced, chip control is maintained, and tool life is extended. The tool geometry enables bi-directional cutting, so the same insert geometry can be used for both forward and reverse turning. This allows all cutting edges of the tool to be utilized, streamlines setup times, and, depending on the situation, enables higher feed rates during reverse turning due to chip thinning caused by the setup angle.

The WL system is further enhanced by its internal precision cooling, which directs coolant to both the top and bottom of the insert directly into the cutting zone. This reduces the thermal load on both the insert and the workpiece, maintaining consistent surface quality even when turning demanding materials. The WL system is suitable for roughing, finishing, profiling, and dynamic turning for both external and internal operations—from small precision parts to large profiles. Typical applications include various shafts, bearing and valve components, and shaped and main grooves, requiring different radii and infeed angles. The secure insert clamping and precision cooling keep chip formation stable, reduce vibration, and extend tool life, even when machining challenging materials.

Diverse Insert Geometries for All Turning Needs

With three cutting edges, WL inserts offer a direct cost advantage compared to traditional two-edged V- and D-geometry inserts. The WL insert clamping system also ensures precise positioning each time the insert is indexed. The same turning holder can accommodate four insert types—neutral, left, right, and full radius—allowing you to switch between turning applications without changing the toolholder.

The range of geometries covers both finishing and roughing: alongside the core FP4/FM4/MP4/MM4 range, the full-radius MU6 is ideal for profiling and complex radii, and the ground FM2 geometry provides light cutting and consistent surface finish in demanding finishing operations. The MN2 geometry is optimized for aluminum and other non-ferrous metals, featuring a polished chipbreaker and high positive rake for low cutting forces, while the RM4 and RP4 roughing inserts offer chipbreakers that combine high feed rates with extended cutting edge durability.

Round-nosed WL inserts are available with radii from R1.0 to 3.0 mm, enabling dynamic turning and profiling with the same three-edged WL system. The range of machinable materials extends from steel, cast iron, and stainless steel to aluminum and hard-to-machine superalloys—and for hard turning, CBN grades are also available.

For tool coatings, the WL system offers both PVD and CVD options, with the unique, patented Tiger·tec® Gold multilayer coating standing out in particular, combining wear resistance, consistent chip formation, and long tool life. This lowers per-part costs in both finishing and roughing operations.

Sizes and Holders for Every Turning Situation

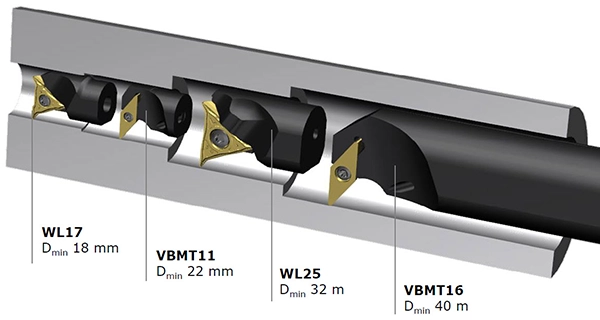

WL inserts come in two sizes. The WL25 covers the standard size range for both external and internal turning. Typical copy turning approach and replication angles generally range between 30 and 50 degrees, and the WL system also supports a neutral 72.5-degree approach angle, which makes it easier to machine different shoulders, pockets, and grooves in both finishing and medium-duty turning. The WL17 is designed for smaller diameter turning, such as Swiss-type long turning machines and internal turning. It uses the same three-edged principle with high form and chip capacity. The WL17 insert enables internal turning down to a bore diameter of just 18 mm, expanding its application range compared to conventional V-geometry inserts.

For external turning, the WL system offers traditional shank holders from 12×12 mm up to 25×25 mm, as well as Walter Capto™ solutions in sizes C3–C6, allowing direct use on multi-axis lathes and turning centers without adapters. For internal turning, shank diameters range from 12–40 mm, and for vibration-damped turning bars, WL system tools can be attached with the quick QuadFit connection (Q32–Q50). All toolholders direct cooling directly to the top and bottom of the insert tip, improving chip control and extending tool life, especially in challenging materials.