Mastercam toolpaths

Mastercam offers a wide range of software and add-ons for programming various machine tools to meet diverse needs. These include Mastercam Mill, Mastercam Mill 3D, Mastercam Lathe, Mastercam Mill-Turn, and Mastercam Multiaxis. With these tools, you can program 3-5 axis machining centers, gantry and long-bed milling machines, CNC lathes, Swiss-type lathes, vertical lathes, and multi-function lathes equipped with a B-axis. The software allows you to create toolpaths for conventional machine shop parts, 3D shapes such as mold making, as well as multi-axis toolpaths for jobs like 5-axis machining. On this page, we introduce the possibilities, benefits, and applications of different toolpaths, and provide tips for the efficient use of these operations.

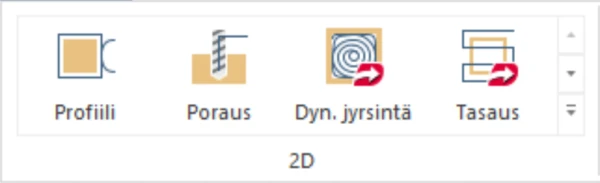

Mastercam Mill 2D Toolpaths

The Mastercam Mill 2D license offers powerful toolpaths for 2D and 2.5D machining operations such as facing, pocketing, slotting, and drilling. An intuitive user interface ensures easy programming, fast and precise part production, and cost-effective, high-quality machining on various machine tools. It's the perfect solution for machine shop parts!

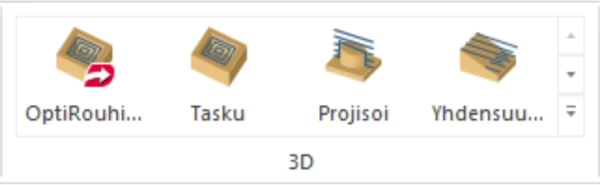

Mastercam Mill 3D Toolpaths

Mastercam Mill 3D provides powerful tools for programming 3-axis toolpaths on 3D surfaces. You can flexibly define avoidance geometries, fixtures, and boundary curves. It's an excellent choice for mold making and for machining complex 3D surfaces. A perfect solution for precise and efficient machining across various industries!

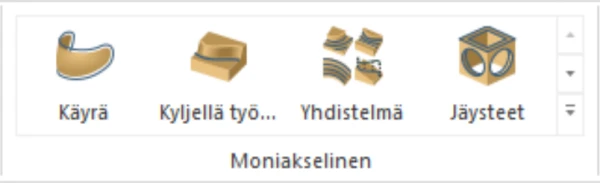

Mastercam Multiaxis Toolpaths

Mastercam Multiaxis offers versatile tools for programming 3-, 4-, and 5-axis toolpaths. Ideal for 5-axis machining centers and B-axis multi-function lathes, but also works on 3-axis machines. An innovative combination operation makes even complex machining processes easy, enhancing manufacturing flexibility and efficiency. A perfect solution!

Mastercam Lathe Toolpaths

Mastercam Lathe provides comprehensive toolpaths for turning operations, suitable for CNC lathes, Swiss-type lathes, and multi-function lathes. Advanced features like dynamic turning and PrimeTurning™ improve efficiency, extend tool life, and reduce issues. Mastercam Lathe ensures precise and efficient turning, increasing manufacturing flexibility and quality.

Mastercam Lathe provides comprehensive toolpaths for turning operations, suitable for CNC lathes, Swiss-type lathes, and multi-function lathes. Advanced features like dynamic turning and PrimeTurning™ improve efficiency, extend tool life, and reduce issues. Mastercam Lathe ensures precise and efficient turning, increasing manufacturing flexibility and quality.

Mastercam Toolpaths – Efficient and Precise Machining for All Needs

Mastercam is a globally renowned leading CAM software that offers a wide range of toolpath programming solutions to cover all types of manufacturing needs. The software supports both traditional and advanced machining processes, enabling precise and efficient machining of both simple and extremely complex parts. Mastercam’s versatility includes programming for 3–5-axis machining centers, CNC lathes, Swiss-type automatic lathes, gantry and long-bed milling machines, as well as multifunction lathes with a B-axis.

Mastercam allows for the design of toolpaths for traditional machine shop parts, the production of 3D shapes such as molds and specialty parts, as well as multi-axis and dynamic machining requirements. The software is flexible and adaptable for various industries, from small workshops to large-scale manufacturers. With Mastercam, you can optimize machining strategies, improve productivity, reduce machining errors, and maximize machine utilization.

Mastercam Mill 2D toolpaths provide an effective solution for 2D and 2.5D machining operations such as facing, pocket and slot milling, and precision drilling. Its intuitive interface speeds up programming, and smart strategies ensure high-quality and cost-efficient manufacturing.

Mastercam Mill 3D toolpaths enable the creation of precise 3-axis machining paths for complex 3D surfaces. The software provides tools for managing avoidance geometry, fixtures, and containment boundaries, making it an ideal solution for mold making, prototyping, and demanding freeform surface machining.

With Mastercam Multiaxis toolpaths, you can program 3-, 4-, and 5-axis machining operations with versatility. The Multiaxis module allows for efficient and safe machining of complex parts—such as cylindrical and curved surfaces and hard-to-reach areas—in a single setup. Innovative strategies like combined operations and dynamic transitions make multi-axis machining more flexible and reduce setup times.

Mastercam Lathe toolpaths offer top-tier solutions for CNC turning, Swiss-type turning, and multifunction turning. Advanced features like dynamic turning and PrimeTurning™ significantly enhance chip control, tool life, and machining quality. Mastercam Lathe enables both simple basic turning operations and demanding complex shapes to be executed accurately and efficiently.

The Mastercam software also supports special features such as optimizing cutting strategies by material, machine-specific post-processors, support tools for multi-axis interpolation, and simulation and verification tools to ensure the safety and accuracy of toolpaths before machining.

Mastercam’s comprehensive toolpath selection enables you to combine high quality and production efficiency in manufacturing projects of any size. Choosing the right toolpath and utilizing optimal settings reduces machine wear, improves part quality, and shortens production times, providing a significant competitive advantage for companies targeting both domestic and international markets.

Camcut offers extensive support for using different Mastercam modules, and in our support section you can learn more about the benefits, features, and best practices of each toolpath module—welcome to develop your machining skills and production processes with us!