Geometric tolerances

Geometric tolerances are a critical part of technical product documentation and are used to define the precise geometric characteristics of parts and components. Tolerances ensure that product parts meet required quality and functional standards, thus reducing the risk of errors and incompatibilities during assembly and use.

The Importance of Geometric Dimensioning and Tolerancing

Geometric tolerances are an essential part of the Geometrical Product Specifications (GPS) system, which provides a standardized language for defining and communicating product geometry in technical documentation, such as engineering drawings. GPS enables unambiguous documentation and communication of product geometry requirements, minimizing the risk of errors and misunderstandings in design, manufacturing, and inspection.

ISO GPS and ASME Y14.5

There are two major geometric tolerancing systems used internationally:

ISO GPS (Geometrical Product Specifications):

- Widely used in Europe and many other countries.

- Defines geometric tolerances through a series of standards, the most important of which is ISO 1101, specifying tolerances for form, orientation, location, and runout.

ASME Y14.5:

- Has a strong presence, especially in North America.

- Provides a similar, but slightly different system for defining geometric tolerances.

Categories of Geometric Tolerances

Geometric tolerances are divided into four main categories: form, orientation, location, and runout tolerances. Each category includes different tolerances used to describe various geometric features of a part.

Form Tolerances

Form tolerances define the shape of individual geometric features, without reference to other features. They specify how accurately a particular feature must conform to the defined geometry.

Straightness

Specifies how straight a feature's line or axis must be. Straightness tolerance can be applied to either a line or a surface.

Flatness

Specifies how flat a surface must be. The flatness tolerance limits surface deviation so the surface stays within a defined allowable range.

Circularity (Roundness)

Cylindricity

Specifies how closely a cylindrical feature must resemble a perfect cylinder, including both circularity and a combination of straightness and flatness.

Profile of a Line

Profile of a Surface

Orientation Tolerances

Orientation tolerances define the relative orientation of geometric features. These tolerances compare one feature with another or a specific reference.

Parallelism

Perpendicularity

Specifies how perpendicular a feature is to a particular reference. For example, this applies to a 90-degree angle between two surfaces.

Angularity

Specifies the angle of a particular feature relative to a reference. The angle can be any value, not just 90 degrees.

Profile of a Line

Profile of a Surface

Location Tolerances

Location tolerances define the position of geometric features relative to one another. These tolerances ensure that features are located precisely in relation to each other.

Position

Concentricity (for centers)

Coaxiality (for axes)

Symmetry

Profile of a Line

Profile of a Surface

Runout Tolerances

Runout tolerances define the position and orientation of a feature as it rotates around an axis. These tolerances ensure feature balance and precision in rotating applications.

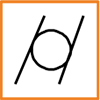

Circular Runout

Specifies the deviation of a feature as it rotates around an axis, taking into account both orientation and position.

Total Runout

A broader measure of runout, specifying the deviation of an entire surface as it rotates around an axis—including all orientation and position deviations.

Geometric Tolerance Symbols

Geometric tolerance symbols are standardized icons that are drawn in a rectangular tolerance frame on drawings. The tolerance frame provides the following information, in order:

- Tolerance symbol: For example, the straightness symbol

- Tolerance value: For example, “0.1 mm”.

- Additional features (if needed): Such as material-related requirements.

- Datums: Indicates which other elements the tolerated element is referenced to.

- The tolerance frame is attached to the item being tolerated with a leader line, usually ending in an arrow or dot pointing precisely to the specified feature.

Dimensional Tolerances and Geometric Tolerances

Geometric tolerances supplement dimensional tolerances. Dimensional tolerances (ISO 14405) define the permissible limits for part dimensions, while geometric tolerances (ISO 1101) specify more detailed geometric characteristics of certain features, such as straightness, flatness, and parallelism. Geometric tolerances provide more precise information about the tolerances of the functional parts of a component, which dimensional tolerances alone cannot describe.

Measurement Techniques and Geometric Tolerances

Measurement methods used to specify and verify geometric tolerances must comply with strict standards and guidelines. Various measurement tools, such as coordinate measuring machines (CMM), can accurately define and inspect geometric tolerances. Calibration of measuring instruments and reporting of measurement uncertainties are key aspects of the GPS standard’s requirements, ensuring that measurements are reliable and traceable to international or national standards.

Summary

Geometric tolerances are an indispensable part of technical drawings and product documentation, providing an accurate and unambiguous means of defining and communicating product geometric features. Geometric tolerances are standardized by international systems like ISO GPS and ASME Y14.5, which set the symbolic language and requirements for geometric accuracy and measurement. When used correctly, geometric tolerances improve product quality, reduce errors, and ensure component compatibility, thus facilitating the entire manufacturing process and the end use of products.

Geometric tolerances are widely used in CAD/CAM systems and measurement software that support ISO GPS. They enable the implementation of precise and consistent quality control practices in various production processes. When correctly applied, geometric tolerances reduce quality issues, improve product and component fit and reliability, and support compliance with technical standards and regulations.

In conclusion, geometric tolerances are essential across all technology and manufacturing industries, where they help to control and ensure the geometric accuracy and quality of products or components.