Geometric Tolerances Form Flatness

Flatness is a form tolerance that defines how much a surface is allowed to deviate from the ideal, perfectly flat plane. It limits surface height differences and waviness so that the surface stays within a defined tolerance zone. This is especially important when the surface serves as a joint surface, sealing surface, or support surface.

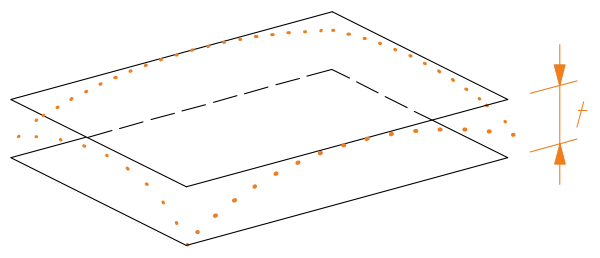

The flatness tolerance zone is formed between two parallel planes, the distance between which corresponds to the tolerance value specified in the drawing. All points on the actual surface must be located between these boundary planes. The smaller the value, the flatter the surface must be manufactured.

Applications

- Joint surfaces: Flatness ensures that two surfaces fit tightly together without gaps or mounting issues.

- Sealing surfaces: If flatness is not controlled, the seal may leak or wear unevenly.

- Machining accuracy: The flatness tolerance specifies how much "warping" or waviness is allowed on the machined surface.

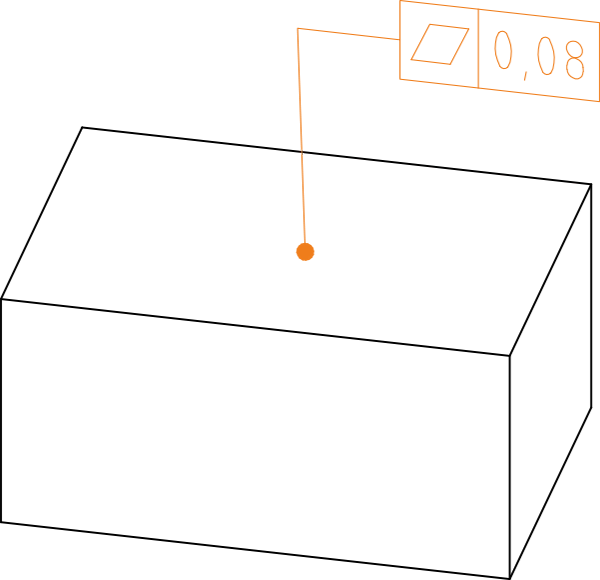

Notation and interpretation

The measured (actual) surface must be between two parallel planes, spaced 0.08 apart.

Definition of the tolerance zone

The tolerance zone is limited in the indicated direction by two parallel planes, spaced t apart.

Significance in manufacturing

Flatness tolerance makes it easier to ensure part compatibility and guarantees proper function in use. For instance, if the joint surface of a machine bearing seat or valve is not sufficiently flat, it could lead to uneven loading, excess wear, or leaks. However, an overly strict flatness requirement can significantly increase manufacturing costs, as fine finishing and precision measurement of the surface demand more time and specialized equipment.

Controlling flatness is thus a balancing act between functional quality and manufacturing economy.