Geometric Tolerances Form Profile any line

The profile of a line is a form tolerance that defines how precisely an individual cross-sectional line of a surface follows its theoretical profile. In other words, it controls the shape of the surface within the plane of a single line, but does not yet control the three-dimensional shape of the entire surface. Profile of a line is important when the part has, for example, curved or beveled shapes that need to closely match the designed geometric profile.

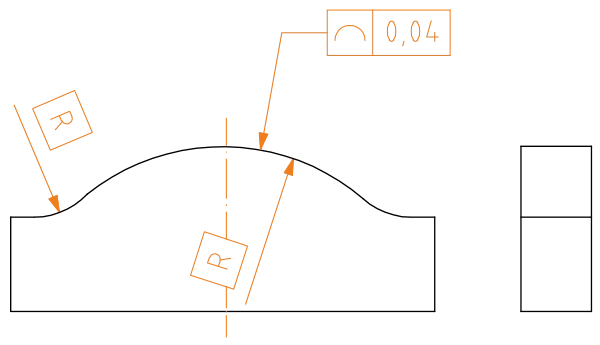

The tolerance zone is formed between two lines that follow the designed profile. These lines are usually parallel, and the distance between them corresponds to the tolerance specified on the drawing. All points of the inspected profile must lie within this zone.

Applications

- Curved surfaces: Ensuring that the surface shape strictly follows the designed curve, for example, in aerodynamic surfaces or cast parts.

- Bevels and form features: The profile of a line tolerance can control the exact geometry of a bevel or other shape feature.

- Casting and molded parts: Profile tolerances are especially useful for complex shapes where a single dimension is not sufficient to define accuracy.

Indication and Interpretation

Each measured (actual) line of the surface, oriented in the direction shown in the drawing, must be between two lines that are a constant distance apart. The separation of these lines is defined by a circle with a diameter of 0.04, and they are placed symmetrically on either side of the theoretically accurate geometric line.

Definition of Tolerance Zone

The tolerance zone is limited by two envelope curves generated as the center of a circle with diameter t moves along the theoretically correct line.

Significance in Manufacturing

The profile of a line tolerance is an essential aspect of ensuring both the functionality and appearance of a product. If the shape deviates too much from the design, parts may not fit together or may cause functional problems, such as increased aerodynamic drag or leaks in seals. At the same time, it's important to note that overly tight profile tolerances will increase manufacturing costs, as higher precision requires more complex manufacturing methods and measurements.

Therefore, the profile of a line tolerance is a compromise: it specifies how closely the surface profile must follow the intended shape for proper function and appearance, but without unnecessarily complicating the manufacturing process.