Geometric Tolerances Form Profile Any Surface

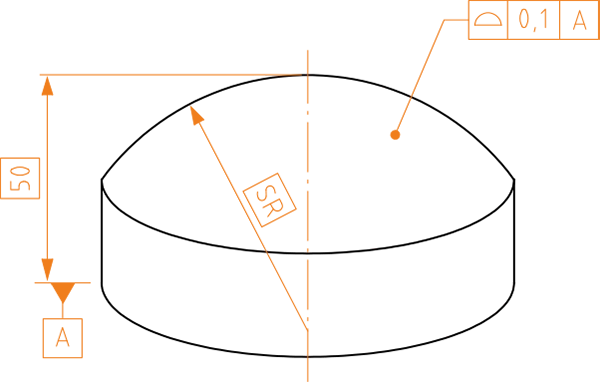

Surface form is a form tolerance that specifies the allowable deviation of an entire surface’s three-dimensional geometry from its intended design. While profile of a line examines the accuracy of a single cross-sectional line, surface form applies the same concept across the entire surface. The tolerance ensures the manufactured surface follows the designed geometry—whether it’s a flat plane, arc, free-form surface, or a complex 3D shape.

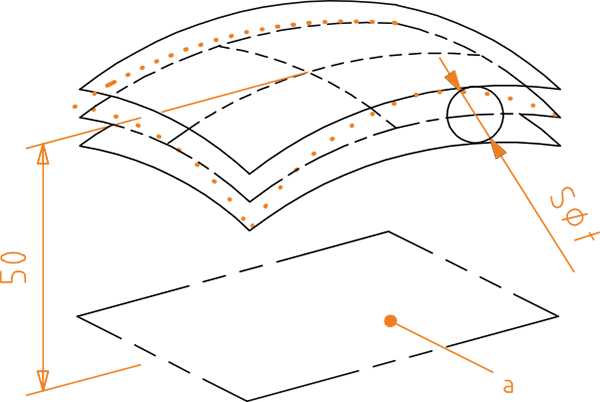

The tolerance zone is defined between two boundary surfaces that correspond to the designed surface. The distance between these surfaces is the tolerance value specified in the drawing. All points of the actual surface must be located within this three-dimensional zone.

Applications

- Free-form surfaces: e.g., plastic components, castings, and molds where precise shape control is critical.

- Aerodynamic surfaces: the shapes of aircraft, cars, or other flow-dependent structures, where deviations may affect performance.

- Sealing and mating surfaces: ensures that parts fit together and seal properly.

Symbol and Interpretation

Every measured (actual) line parallel to datum plane A, as defined by each cross-section identifier on the surface, must lie between two lines that are spaced at a constant distance from each other, where that distance is specified by a 0.1 diameter circle, and these lines are symmetrically placed on either side of the geometrically correct line. The line’s location is defined by datum planes A and B.

Definition of the Tolerance Zone

The tolerance zone is bounded by two envelopes that are generated by moving the center of a circle with diameter t along the geometrically correct line, whose position is defined by datum planes A and B.

Importance in Manufacturing

Surface form tolerance is one of the most versatile and widely used geometric tolerances, as it enables control of the entire surface’s precision with a single symbol. It is especially suitable for complex and free-form surfaces that cannot easily be controlled by individual dimensions.

Setting a surface form tolerance that is too loose may lead to compatibility issues, leaks, or diminished performance. Conversely, a tolerance that is too tight will significantly increase manufacturing costs, as it requires precise machining and careful measurement, for example, with a coordinate measuring machine (CMM).

According to the ISO 1101 standard, surface form tolerance provides designers and manufacturers a common language to ensure that complex surfaces remain sufficiently close to their intended geometry to ensure function and quality.