Geometric Tolerances Form Roundness

Circularity (also known as roundness) is a form tolerance that specifies how closely a circular cross-section conforms to an ideal circle. It limits deviations such as ovality, eccentricity, and waviness, ensuring the cross-section of a part stays within a defined tolerance zone. Circularity is one of the fundamental form tolerances defined in the ISO 1101 standard.

The tolerance zone is formed between two concentric circles, with a distance between them matching the tolerance indicated on the drawing. All points of the measured feature must lie between these circles. Unlike many other tolerances, circularity does not reference any datum, but pertains solely to the feature’s own shape.

Applications

- Shafts and holes: Ensures shafts fit into bearings without excessive play or point loading.

- Sealing surfaces: A uniform shape prevents leaks and wear.

- Rotating components: Adequate circularity reduces vibration and imbalance in machinery.

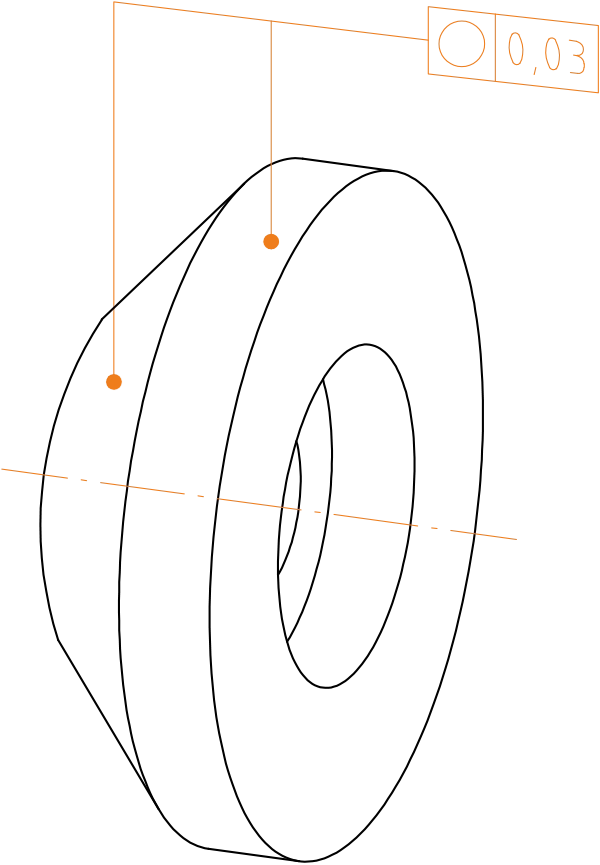

Notation and Interpretation

For both cylindrical and conical surfaces, the measured (actual) outline of every cross-section must fall between two concentric circles, lying in the same plane, whose radial distance is 0.03.

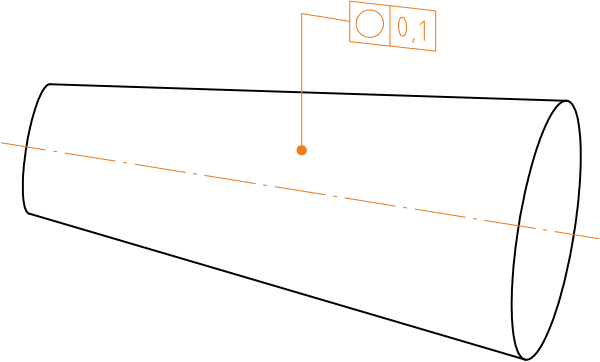

Definition of the Tolerance Zone

For a revolving surface and a sectioned cone (whose axis matches the fitted revolving surface's axis and whose base curve is perpendicular to the surface), the measured (actual) outline at each section must lie within the conical tolerance zone defined by two circles spaced 0.1 apart (this distance is measured from the base curve).

Importance in Manufacturing

Circularity is a critical factor in precision engineering. If a shaft or hole isn’t round enough, it can lead to uneven loading, noise, vibration, or premature wear. On the other hand, requiring excessively tight circularity can drive up manufacturing costs, as achieving and measuring it requires specialized techniques and high precision.