Geometric Tolerances Form Straightness

Straightness is a form tolerance that defines how precisely a line, edge, or axis follows an ideal straight line. It is one of the simplest and most important geometric tolerances because it controls the basic shape accuracy of a part without referencing any datum. Straightness is classified as a basic tolerance defined in the ISO 1101 standard.

Straightness tolerance can apply to two different situations:

- Surface straightness – controls a line on a surface so that it does not deviate from the ideal straight line more than the value specified in the frame.

- Axis straightness – controls the centerline of a cylindrical feature, which must stay within the allowed tolerance zone.

The tolerance zone is formed between two parallel lines (or, in the case of an axis, between two cylindrical surfaces), the distance between which is the tolerance value given on the drawing. All points of the inspected feature must fit within this zone.

Applications

- Machined edges and guides: ensures that a part moves smoothly without jerking or jamming.

- Axes: straightness is critical in rotating parts, where even small deviations can cause vibration and uneven wear.

- Mating surfaces: prevents incorrect fits and ensures that joints work correctly.

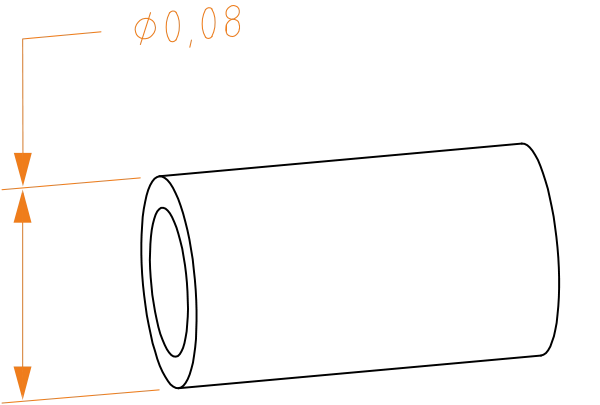

Notation and interpretation

The measured (actual) axis of the toleranced cylinder must lie inside a cylinder with a diameter of 0.08.

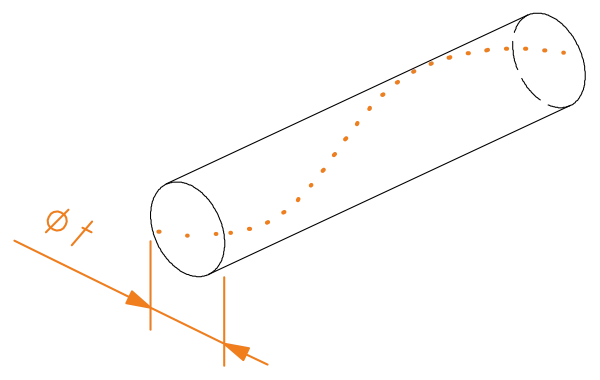

Definition of the tolerance zone

If the symbol Ø is placed in front of the tolerance, the tolerance zone is limited by a cylinder with a diameter of t.

Significance in manufacturing

Straightness is one of the most commonly used form tolerances, as it allows control of the basic shape of a part without having to define its relationship with other features. Too large a deviation can cause functional problems, such as gaps at joints, misalignment, or uneven movement. On the other hand, overly tight straightness tolerances increase manufacturing costs, since they require precise machining and often measurements with devices like a coordinate measuring machine (CMM).

Managing straightness is thus a balance between functional quality and cost-effective manufacturing.