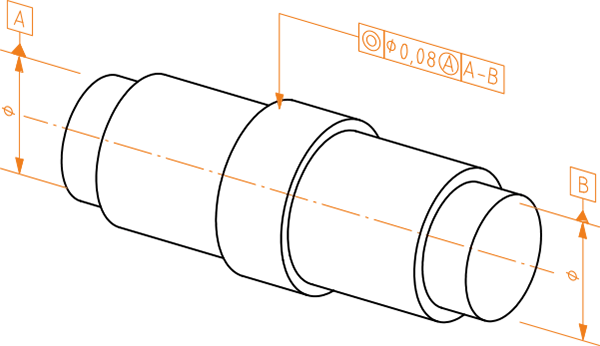

Geometric Tolerances Location Concentricity (for axes)

Concentricity for axes is a positional tolerance that specifies how precisely the axes of two or more cylindrical features align with each other. It acts as a kind of “three-dimensional” extension of concentricity for center points: instead of just evaluating a point in a cross-sectional plane, the entire position of the axis is considered.

The tolerance zone is defined as a cylinder whose diameter equals the tolerance value given in the drawing. The axis of the feature being inspected must be located within this zone in relation to the reference axis, or datum. This ensures that the axes of different features are exactly aligned with each other.

Applications

- Axes and holes: ensures the shaft aligns with the hole or sleeve, preventing misalignment and uneven loading.

- Bearings and rotating parts: concentricity prevents vibration, noise, and excessive wear.

- Multi-part assemblies: accurately aligning multiple cylindrical features on the same centerline ensures parts work together as designed.

Marking and Interpretation

The measured (actual) centerline of the toleranced cylinder must be within a cylindrical area with a diameter of 0.08, whose centerline is the common reference axis A–B.

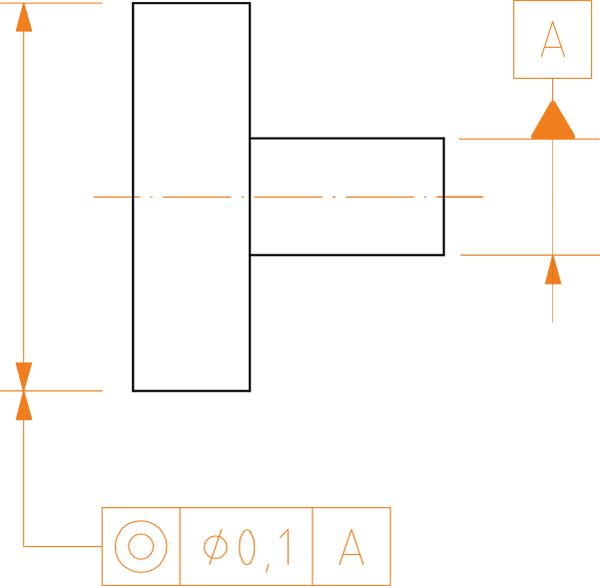

Definition of Tolerance Zone

The measured (actual) centerline of the toleranced cylinder must be within a cylindrical area with a diameter of 0.1, whose centerline is reference axis A.

Importance in Manufacturing

Concentricity of shafts is especially important in rotating components. If the shafts are not precisely aligned, imbalance occurs, which can cause vibration, noise, and rapid wear. Accurate alignment is also essential for successful assembly, since misalignment can prevent parts from fitting together at all.

At the same time, requiring excessively tight concentricity raises manufacturing costs and demands precise machining as well as accurate measurements, for example with a coordinate measuring machine (CMM). That’s why it’s important to choose the appropriate tolerance based on the intended use.

In the ISO 1101 standard, concentricity for axes is defined as a form of positional tolerance, ensuring that axes remain perfectly aligned along their entire length.