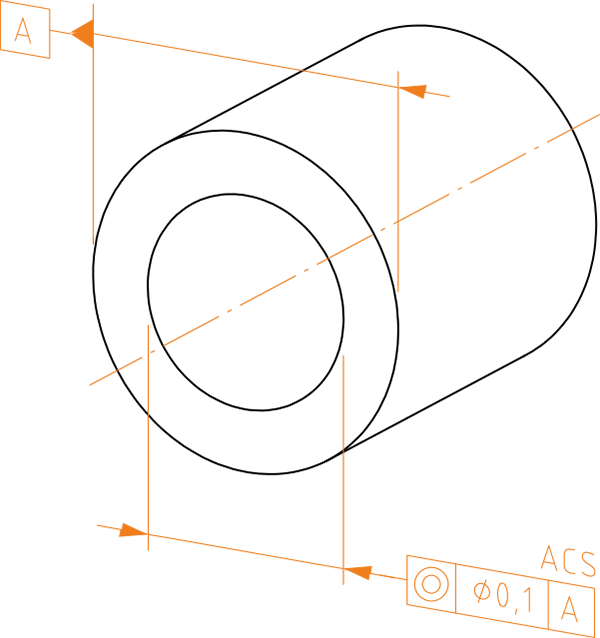

Geometric Tolerances Location Concentricity (for center points)

Concentricity of centers is a positional tolerance used to ensure that the centers of two or more circular features are aligned. This definition applies to features within a cross-sectional plane: for example, the center of a hole must be located at the same point as the center of the associated outer diameter.

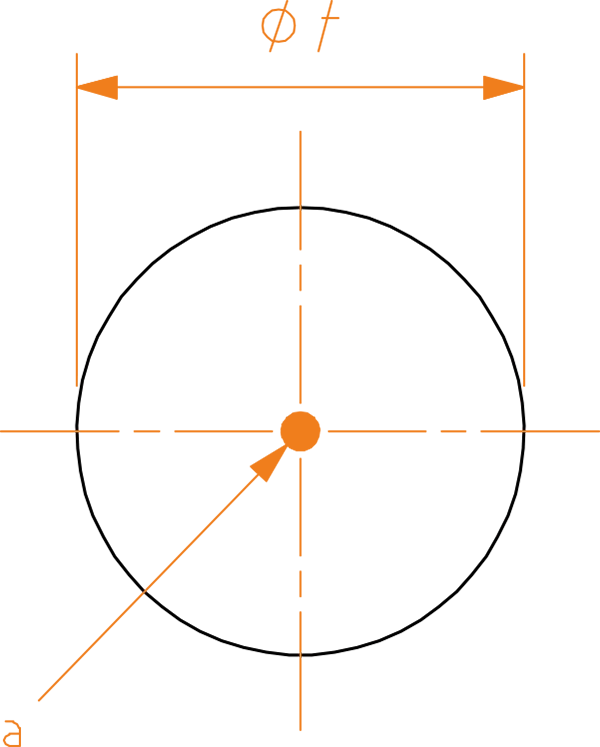

The tolerance zone consists of a circle whose diameter is equal to the tolerance value indicated on the drawing. The actual centers of the features must lie within this circle relative to a reference point or datum. This ensures that, within the cross-sectional plane, the features remain concentrically positioned.

Applications

- Holes and outer diameters: ensures that a hole is precisely located at the center of the axis.

- Connection points: when multiple features must be matched together without clearance, concentricity of the centers is essential.

- Guiding features: for example, in bearing housings where the inner and outer features must share exactly the same center to ensure proper load distribution.

Notation and interpretation

The measured (actual) center of the inner circle must, in all cross sections, be within a circle with a diameter of 0.1, centered at reference point A in the same section.

Definition of the tolerance zone

The tolerance zone is limited by a circle with a diameter t; the Ø symbol must be used before the tolerance value. The center of the circular tolerance zone is the reference point.

Significance in manufacturing

Concentricity of centers is especially important in parts that require precision fits or where even minor inaccuracies could cause functional issues. If the centers are not precisely aligned, the result can be misalignment, excessive play, or skewed joints. At the same time, it’s important to note that overly tight tolerances increase manufacturing costs, since highly precise machining and measurement are required.

Concentricity for centers provides designers and manufacturers with a clear tool to ensure that critical features precisely coincide in the cross-sectional plane — in accordance with ISO 1101.