Geometric Tolerances Location Position

Position is a location tolerance that defines the location of a feature—such as a hole, shaft, slot, or pin—in relation to other features or datums. It is one of the most commonly used geometric tolerances, as it allows for precise placement of holes and ensures that parts fit together as intended in the design.

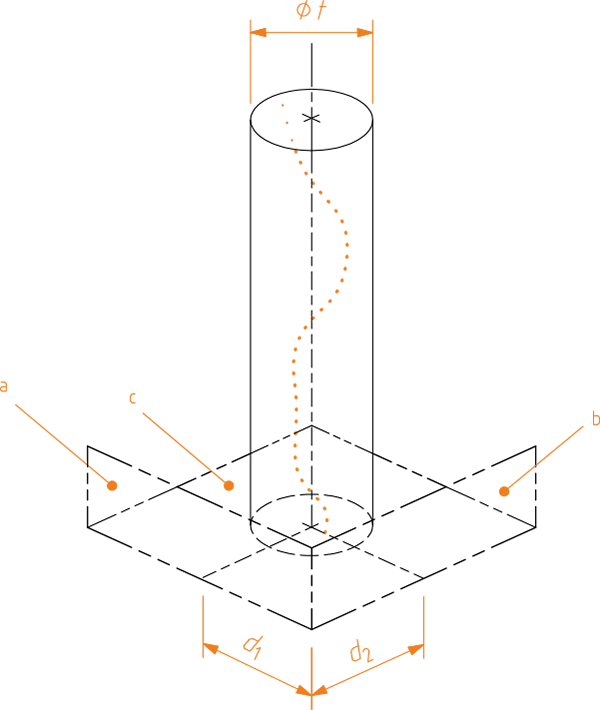

Positional tolerance simultaneously controls three things: location, orientation, and form. It defines the allowable deviation of a feature’s centerline or center point from its ideal location. The tolerance zone is typically a cylindrical or rectangular area into which the measured feature’s actual center point or axis must fit.

Applications

- Holes and bolt patterns: ensuring that holes are in the correct position relative to each other and the mounting surface.

- Shafts and pins: precise location ensures that rotating components and joints function as designed.

- Machine part assemblies: positional tolerance prevents gaps or stress in joints caused by parts being incorrectly positioned.

Indication and Interpretation

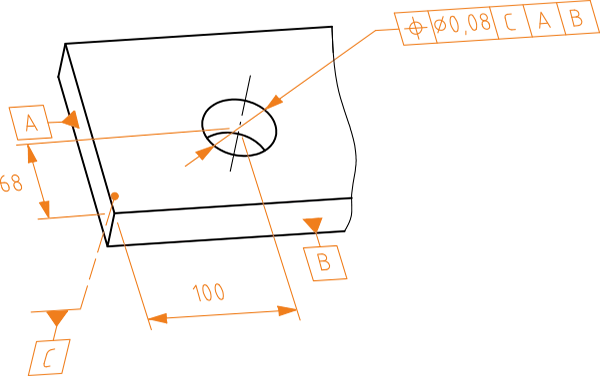

The measured (actual) centerline must be within a cylindrical area with a diameter of 0.08, with its axis aligned with the theoretically exact position of the hole, considering datum planes C, A, and B.

Definition of the Tolerance Zone

If a symbol is placed in front of the tolerance, the tolerance zone is limited by a cylinder with a diameter of t. The axis of the tolerance zone is defined using theoretically exact dimensions based on the datum features C, A, and B.

Importance in Manufacturing

Positional tolerance allows for some flexibility without compromising the functionality of the parts. For example, if holes are not positioned accurately enough, bolts may not fit, joints may not be rigid, or parts may not align correctly. On the other hand, an excessively tight positional tolerance increases manufacturing costs due to the need for precision machining and careful measurement.

In the ISO 1101 standard, position tolerance is a key location tolerance and is one of the most effective ways to control part compatibility and ensure proper function throughout the entire assembly.