Geometric Tolerances Location Profile Any Line

The profile of a line is a positional tolerance that defines how accurately an individual cross-sectional line of a surface is positioned in relation to a datum. Unlike a simple form tolerance, the profile of a line given as a positional tolerance takes into account the reference to which the line is aligned and specifies how much its actual profile can deviate from its intended location.

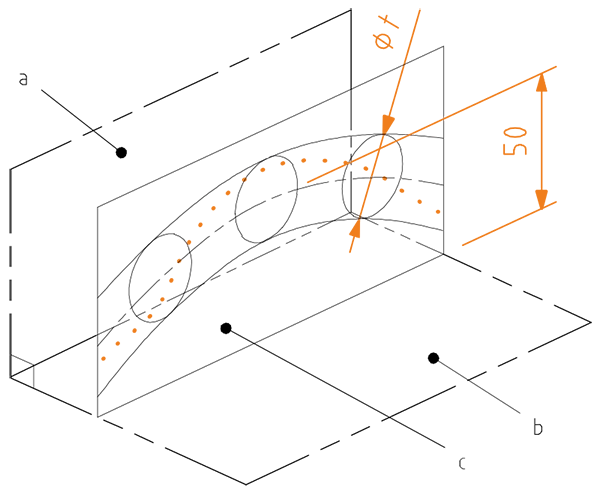

The tolerance zone is formed between two ideal profile lines, with the distance between them indicated as the tolerance on the drawing. The actual cross-sectional line must remain within these boundaries. When datum references are included in the tolerance frame, the location of the profile is precisely defined in relation to them.

Applications

- Chamfers and curved shapes: Ensures that the location of the chamfer or curve is correct relative to other surfaces.

- Mating surfaces: When a curved or angled shape must be correctly aligned to a datum, the profile of a line as a positional tolerance keeps it in place.

- Cast and plastic parts: Useful when complex shapes need to be accurately matched in an assembly.

Notation and interpretation

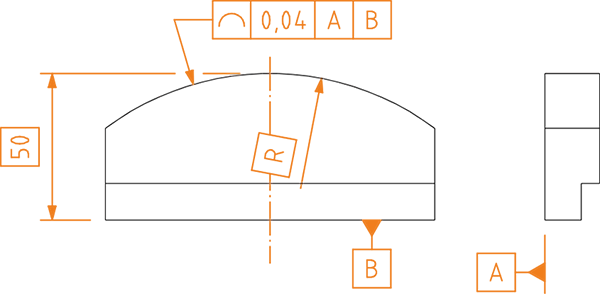

The measured (actual) line, parallel to base plane A and defined for each illustrated plane of the surface, must be between two lines at a constant distance from each other. The distance between these lines corresponds to a 0.04 diameter circle and they are symmetric on either side of the geometrically correct line. The position of this line is defined using datum planes A and B.

Definition of the tolerance zone

The tolerance zone is bounded by two envelopes formed as the center of a circle with diameter t moves along the geometrically correct line, whose position is defined by datum planes A and B.

Significance in manufacturing

The profile of a line as a positional tolerance is a versatile tool because it allows you to control both the accuracy and the position of a line at the same time. If the shape is not in the right position, the parts will not align, leading to gaps or skewed joints. On the other hand, a tolerance that is too tight increases manufacturing costs as it requires precision machining and measurements.

In ISO 1101, the profile of a line is defined as both a form and positional tolerance, allowing its use for simple form control or precise alignment to datums as needed.