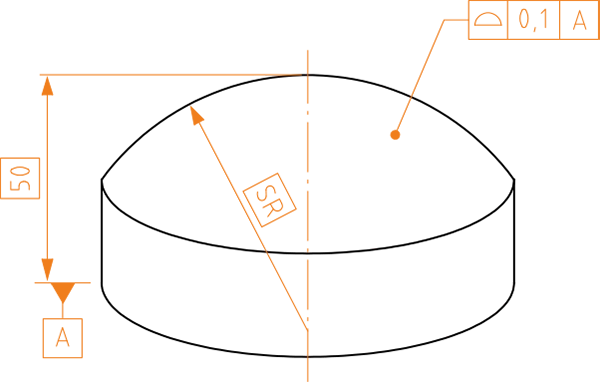

Geometric Tolerances Location Profile Any Surface

The profile of a surface is a positional tolerance that defines the deviation of the entire surface’s actual location and shape relative to datums. It extends the concept of a profile line into three dimensions, controlling not just the surface’s accuracy but also its position in relation to other features. In the ISO 1101 standard, the profile of a surface is one of the key profile tolerances.

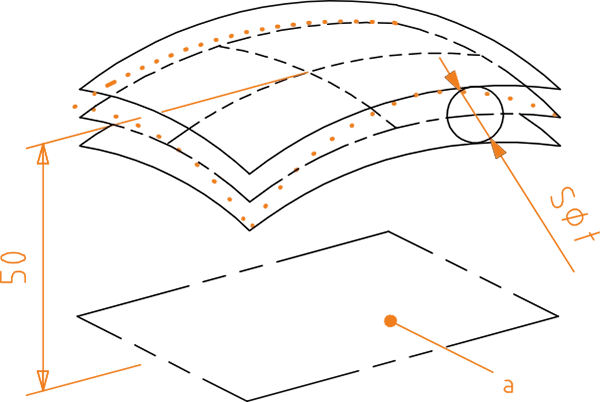

The tolerance zone is formed between two ideal boundary surfaces. The distance between these boundaries is the tolerance value specified in the drawing. All points on the actual surface must lie within this zone. When the feature control frame refers to datums, the profile of the surface and its location are precisely referenced to the datum surfaces or axes.

Applications

- Cast and plastic parts: Enables positioning of complex surfaces relative to datums.

- Aerodynamic surfaces: Ensures that surfaces guiding airflow remain in the precisely designed position.

- Machinery sealing surfaces: Controls the shape and location of surfaces so that joints function without leaks or gaps.

Symbol and Interpretation

Every measured (actual) line of the surface in the direction defined by the sectioning plane designation, parallel to datum A, must be located between two lines that are a constant distance apart. The distance between them is determined by a circle with a diameter of 0.1, and these lines are symmetrically positioned on each side of the theoretically exact line. The location of this line is defined by the datums A and B.

Definition of the Tolerance Zone

The tolerance zone is limited by two enveloping curves, created as the center of a circle with diameter t moves along the theoretically exact line. The position of this line is defined by the datums A and B.

Significance in Manufacturing

Surface profile as a positional tolerance is a powerful tool when the shape and position of a surface relative to other features is critical. If the tolerance is not controlled, parts may not fit together, may be misaligned, or may cause uneven distribution of loads. On the other hand, overly tight tolerances increase manufacturing costs and require measurements, for example with a coordinate measuring machine (CMM).

Surface profile as a positional tolerance combines the control of both the shape and location, allowing the designer to specify the accuracy of the entire surface relative to datums with a unified and clear notation.