Geometric Tolerances Orientation Perpendicularity

Perpendicularity is an orientation tolerance that defines how precisely a feature—such as a surface, edge, or axis—is positioned at a 90° angle relative to a reference surface or axis. It doesn't measure the feature's location, but rather the deviation of its angle from ideal perpendicularity. Perpendicularity is one of the orientation tolerances specified in the ISO 1101 standard.

The tolerance zone is established so that the measured feature must remain within a specified tolerance value relative to the datum. For a surface, the tolerance zone consists of two planes perpendicular to the datum, and the surface must fit between them. For an axis, the zone is a cylinder whose axis is perpendicular to the chosen datum.

Applications

- Holes and pins: Ensures that a hole is drilled exactly at a 90° angle to another surface, so that a pin or bolt seats correctly.

- Machine mating surfaces: For example, frame surfaces that need to be exactly perpendicular to ensure even load distribution.

- Guides and bearing surfaces: Prevents jamming and uneven wear when part movement relies on precise angular positioning.

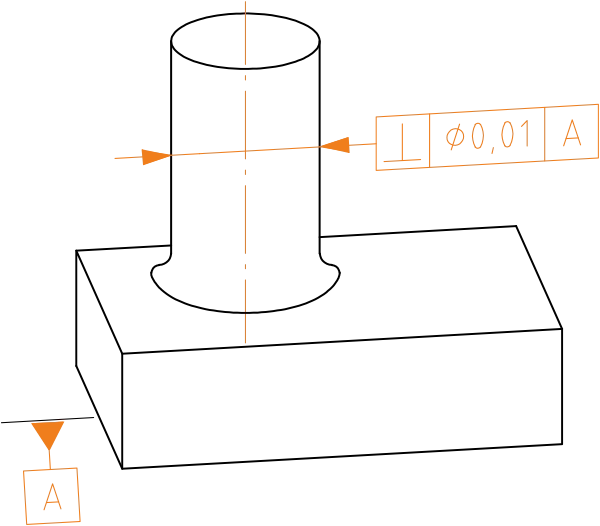

Notation and Interpretation

The measured (actual) centerline of the cylinder must remain within a cylinder of diameter 0.01 that is perpendicular to reference plane A.

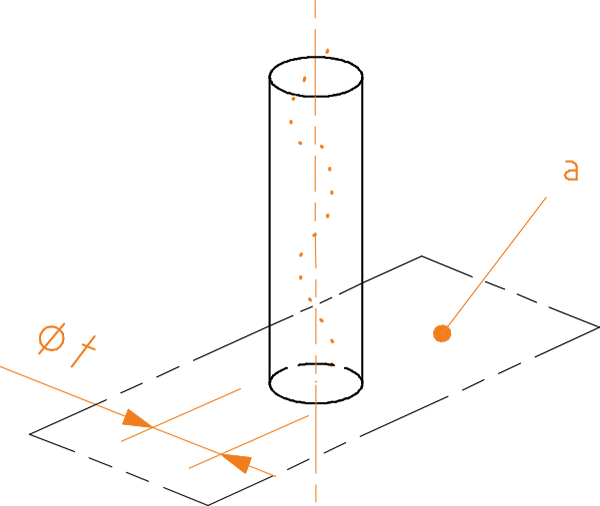

Definition of the Tolerance Zone

If a symbol is marked in front of the tolerance, the tolerance zone is defined by a cylinder of diameter t that is perpendicular to the datum feature.

Significance in Manufacturing

Perpendicularity is a highly important functional tolerance because even a small angular deviation can cause gaps, stresses, or malfunctions in joints. For example, if a bearing housing is not perpendicular to its axis, it can result in uneven load distribution and rapid wear.

On the other hand, specifying overly tight perpendicularity requirements can greatly increase manufacturing costs, since higher accuracy demands precision machining and inspection. Therefore, design needs to strike a balance between practical functionality and manufacturing economy.