Geometric Tolerances Run-out Total Run-out

Total run-out is a run-out tolerance that defines the allowable deviation of a feature during rotational movement across the entire surface. Unlike simple run-out (circular run-out), which looks at deviation in a single cross-sectional plane, total run-out controls the entire surface’s form and position in relation to the rotational axis. In practice, it combines control of circularity, straightness, concentricity, and cylindricity into a single tolerance.

The tolerance zone is constructed so that every point on the feature’s surface, when the part is rotated around its datum, must fit within the tolerance defined in the frame along its full length. This gives total run-out far more comprehensive control than individual circular run-out.

Applications

- Long shafts and cylinders: Ensures the shaft remains straight and balanced throughout its entire length.

- Bearing surfaces: Prevents uneven load distribution and extends bearing lifespan.

- Rotating machine parts: For example, crankshafts, gears, and brake drums where balanced rotation across the whole surface is critical.

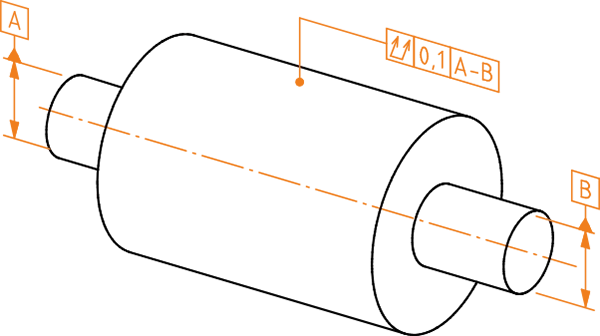

Symbol and Interpretation

The measured (actual) surface must be between two coaxial cylinders with a difference in radii of 0.1, and their axes coincide with the common reference line A–B.

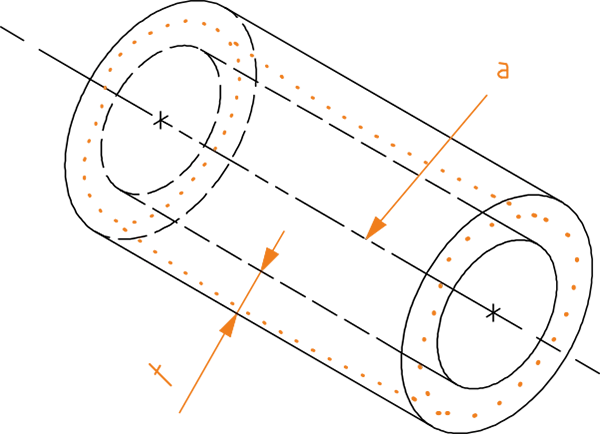

Definition of the Tolerance Zone

The tolerance zone is limited by two coaxial cylinders whose difference in radii is t and whose centerline coincides with the reference axis.

Significance in Manufacturing

Total run-out is a critically important tolerance, especially when balance and full-surface functionality determine whether a part is fit for use. If total run-out is not controlled, it can result in vibration, uneven wear, noise, and even total mechanism failure.

Because total run-out combines various form and positional requirements, it can be strict and demanding from a manufacturing perspective. Tolerances that are too tight can significantly increase costs, since achieving them requires precise machining and careful measurements, often using a coordinate measuring machine (CMM).

According to the ISO 1101 standard, total run-out is defined as one of the key run-out tolerances, enabling assurance that rotating parts maintain quality and reliability throughout their service life.