Geometric Tolerances Shape Cylindricity

Cylindricity is a form tolerance that defines how accurately a cylindrical surface of a part matches the ideal cylinder. In practice, it combines both roundness and straightness requirements: every cross-section must be round, and the entire axis of the cylinder must remain straight. Cylindricity is one of the fundamental form tolerances specified in ISO 1101.

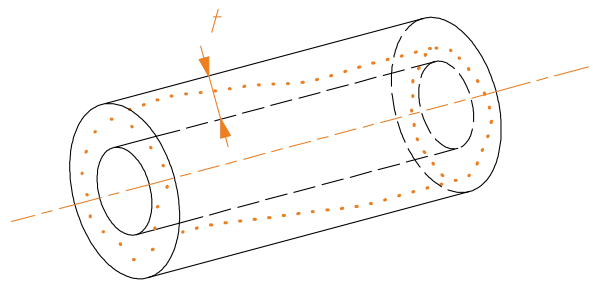

The tolerance zone is defined as the space between two coaxial cylindrical surfaces, with the distance between them equal to the tolerance value specified in the drawing. All points of the actual cylindrical surface must lie within this zone.

Applications

- Shafts: Ensures the shaft is uniformly round and straight along its entire length, which is crucial for compatibility with bearings, bushings, and seals.

- Cylindrical holes: The shape of the hole must remain cylindrical so that, for example, pins or bolts fit reliably.

- Rotating machine parts: Consistent cylindricity reduces vibration, noise, and uneven wear.

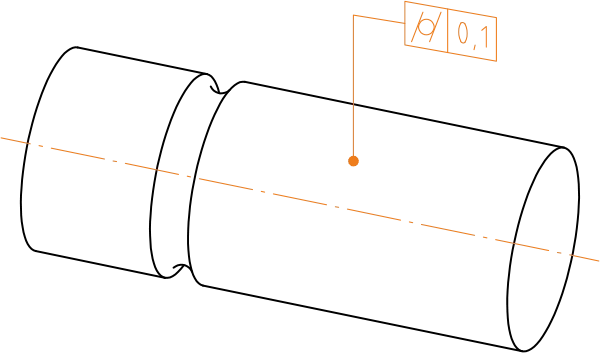

Symbol and Interpretation

The (actual) cylindrical surface must lie between two coaxial cylindrical surfaces that have a radial distance of 0.1.

Definition of the Tolerance Zone

The tolerance zone is bounded by two coaxial cylindrical surfaces, with a radial distance of t between them.

Importance in Manufacturing

Cylindricity is especially critical in precision engineering. If a shaft or hole lacks sufficient cylindricity, parts may load unevenly, leading to faster wear, seal leakage, or even machine failure. On the other hand, requirements that are too strict will increase manufacturing costs, as achieving tighter tolerances requires precision machining and measurement, such as with a coordinate measuring machine (CMM).

Cylindricity tolerance provides a balance between functional quality and manufacturing costs—a level of accuracy sufficient to ensure parts operate properly, but without unnecessary overproduction.