up2parts – Efficiency in Manufacturing Through AI

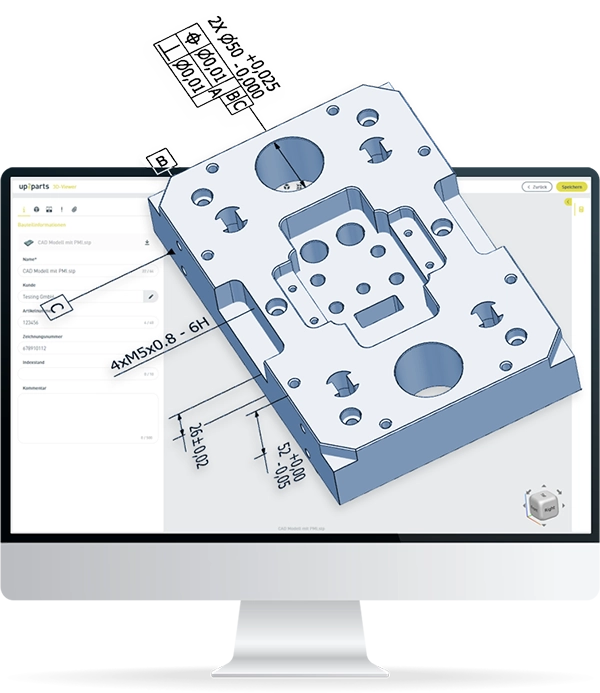

In day-to-day machining operations, fast quotation calculations and consistent programming quality are essential. Yet many companies still struggle with manual estimating, a shortage of skilled personnel and growing cost pressures. up2parts addresses these challenges with an AI-driven software solution that brings together 3D models, PMI (Product Manufacturing Information) and company-specific know-how into a self-learning system. This accelerates quotation calculation, work plan creation and CAM programming while improving overall productivity and data quality.

AI That Learns from the Machine Shop’s Own Expertise

up2parts has been developed directly for the needs of manufacturing companies, and its solutions are based on practical machine shop experience. The software supports quotation calculation, work plan creation and CAM programming by utilizing the company’s existing know-how. It acts as a production copilot that learns from user decisions and adapts to the company’s established methods.

up2parts combines geometric analysis of 3D models with PMI along with production data such as the machines, cutting tools and machining strategies used in the shop. This creates a learning system capable of generating quotation calculations, work plans and CAM proposals within seconds without relying on macros or rule-based logic. The result is an evolving tool that improves estimating and programming efficiency from one project to the next. The manufacturing company retains full ownership of its data, since CAD models, processes and know-how remain entirely under its control. This principle is a core foundation of the up2parts concept.

Geometric Similarity Search Speeds Up Quoting and Standardizes Processes

Geometric similarity search is one of the most effective ways for up2parts to reduce manual work and accelerate cost estimation. The AI analyzes the geometry and features of a 3D model and searches the company’s database for matching or similar components. This allows previously manufactured or calculated parts to be found within seconds without manual browsing or relying on filenames. At the same time, the system identifies which machining methods and tools were used in similar past projects and automatically offers this information as a basis for new components.

When comparable parts are found quickly, the user can leverage existing production knowledge far more accurately than with traditional methods. Process steps, machining strategies and cost structures can be reused with just a few clicks, which shortens the time needed for quotation work and improves the consistency of calculations. The database grows with every new component and forms an increasingly comprehensive, production-based source of knowledge to support future projects.

up2parts calculation – Quotation Estimates and Work Plans in Minutes

Quotation calculation remains one of the most labor-intensive tasks in many machine shops. The process often depends on the personal expertise of senior employees, manual spreadsheets, recollection of previous projects or even programming the part simply to estimate machining time. up2parts calculation solves this by automating steps that have traditionally been considered difficult to digitalize. The software brings consistency and speed to estimating, independent of any single employee’s experience. up2parts calculation runs entirely in a web browser and requires no CAM expertise from the user. It also does not consume the company’s CAM licenses or demand a high-performance workstation, as quotations are generated directly in the browser without additional software.

The process starts by importing a 3D model and PMI from PDF drawings or manually added by the user, after which the AI identifies the geometry, proposes suitable process steps and estimates setup and machining times based on the company’s existing production practices. The user can adjust these suggestions, but the actual calculation is completed automatically within seconds. Many companies have reported up to an 80 percent reduction in quotation time, improving their ability to respond quickly to customer inquiries and increasing their win rate in competitive bidding. At the same time, accuracy improves because the AI relies on the company’s individual production data rather than generic assumptions.

up2parts calculation is especially valuable for high mix low volume production, where manual estimating is time-consuming and often disproportionate to the likelihood of receiving the order. Automation frees time for production planning and ensures that estimating is not dependent on a single person. The company’s tacit knowledge is captured in the system and remains available despite personnel changes, supporting operational continuity and keeping quotation lead times short.

up2parts autoCAM – CAM Programming Up to 70% Faster

CAM programming is a critical phase in many machine shops, where the geometry of the component, the cutting tools and the machining strategies are combined into executable NC code. This step is often labor-intensive and requires significant expertise from the programmer. up2parts autoCAM streamlines this stage by analyzing the geometric features of the 3D model as well as PMI from PDF drawings or manually added by the user together with the company’s own methods and generating automated programming suggestions directly into the existing CAM environment. This improves programming accuracy and standardizes finishing stages where tolerance control is often critical.

up2parts autoCAM automatically creates setups, operations, tooling and cutting parameters, and transfers them to systems such as Mastercam, hyperMILL or GibbsCAM within seconds. The user can adjust the proposals, verify the simulation and generate NC code from the ready-made foundation, which significantly reduces the amount of manual work required. Companies have reported time savings of up to 70 percent, especially for components where traditional programming involves a large amount of repetitive work. Automation does not replace the programmer’s expertise but removes a substantial portion of routine tasks and accelerates the entire process.

Core of the System – A Learning, Company-Specific Database

At the heart of up2parts is a company-specific database that collects all production information relevant to estimating and programming, including machine tools, cutting tools, materials, machining methods, machine hour rates and previously manufactured components with their associated data. With this data set, the AI can recognize the specific characteristics of the company’s production environment and generate suitable process steps and cost proposals as well as CAM proposals including operations and tools.

Because every manufacturing company operates in its own way, a generic automation model would not function reliably across different environments. up2parts addresses this by learning directly from the user. Every approved process step, adjusted calculation and selected tool is stored in the system, gradually building a company-specific and constantly evolving production copilot that adopts the company’s proven practices and applies them to future projects.

The up2parts platform runs entirely in the cloud, but the company-specific database can be stored either in the up2parts cloud environment or, when required by strict security policies, on the customer’s own on-premise servers. Local storage is particularly important in industries with strict data security requirements, such as defense and aerospace. A dedicated company database also supports operational continuity, since production knowledge is not tied to individual employees. The learning system reduces routine work and preserves the company’s expertise so it can be reused from one project to the next.

up2parts as Part of a Modern Digital Production Chain

up2parts delivers the greatest value when it is integrated into a digital production chain where quotation calculation, work plan creation and CAM programming form a unified workflow. When information flows seamlessly from one stage to the next, companies gain a clearer understanding of lead times, resource requirements and costs in both one-off jobs and series production. The software adapts to the company’s machines, tools and machining methods, making it suitable for a wide range of production environments. The development of up2parts is also supported by its industrial partners, including Sandvik, DMG MORI and Schaeffler, who provide extensive technological expertise and ensure long-term advancement of the platform.

Practical experiences from European contract manufacturers show that quotation work becomes faster, process step suggestions become more accurate, and the time required for programming is significantly reduced. Companies also report improved production control and more consistent workflows, as routine tasks shift to automation and skilled personnel gain more time for process development and methods engineering. The learning copilot preserves the organization’s tacit knowledge and ensures that proven practices remain available despite staff turnover, supporting stable and continuous operations.

A Partner That Simplifies the Adoption of Digital Solutions in Machine Shops

Camcut Group has entered into a partnership agreement with the German company up2parts GmbH for the distribution and support of up2parts solutions. As the official partner, Camcut is responsible for software delivery, training and technical support. Its extensive experience with CAM software, production technologies and machine shop processes makes Camcut a strong partner for both implementation and long-term use of the system. Camcut helps customers identify where up2parts provides the greatest benefit and how the solution can be integrated efficiently into existing CAM environments and established production practices. This enables companies to make full use of up2parts and develop their manufacturing toward a more efficient and data-driven environment.

up2parts will be prominently featured at the Konepaja Trade Fair held at the Tampere Exhibition and Sports Centre from March 17–19, 2026, at the Camcut booth in Hall A, stand A722. During the fair, Marco Bauer, CEO of up2parts GmbH, and Mikko Vepsäläinen, CEO of Camcut Group, will discuss the use of self-learning AI in quotation calculation, work planning and CAM programming for machine shops on the main stage on Wednesday, March 18 at 12:00.